|

poradna o diabetes (= cukrovka)

odpověď na Vaše otázky o diabetes

|

TIP: Používáte inzulínovou pumpu? Navštivte komunitní web www.pumpari.cz, naleznete zde nejnovější informace o všech inzulínových pumpách dostupných v ČR.

| Zobrazit předchozí téma :: Zobrazit následující téma |

| Autor |

Zpráva |

FrankJScott

Založen: 26.2.2021

Příspěvky: 5000

Bydliště: 스포츠 관련 정보

|

Zaslal: út březen 28, 2023 3:21 pm Předmět: Good Hints For Deciding On Automated Packaging Machines Zaslal: út březen 28, 2023 3:21 pm Předmět: Good Hints For Deciding On Automated Packaging Machines |

|

|

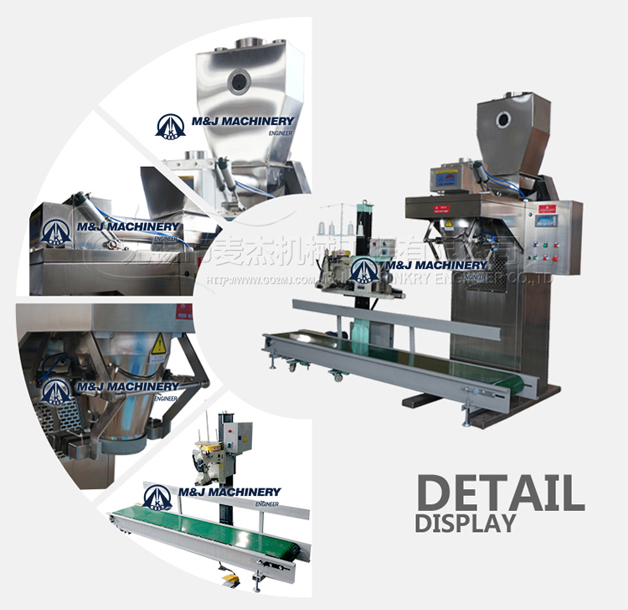

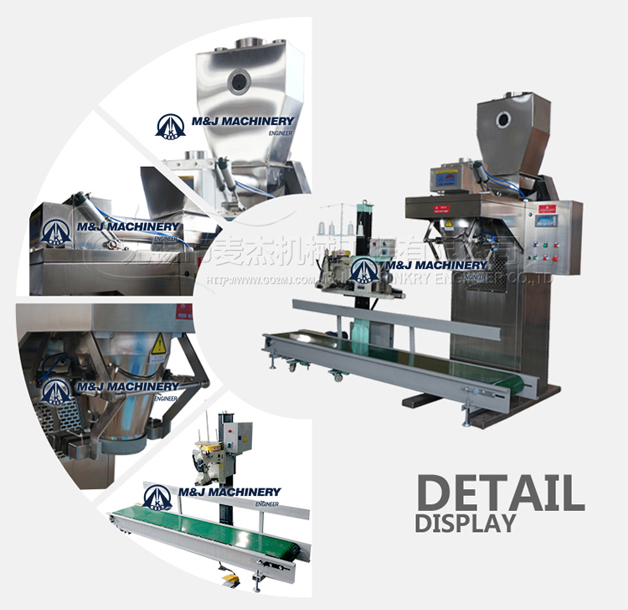

How Do Packaging Machines Differ For Industrial, Food, Cosmetics, Pharmaceutical And Household Products

Packaging equipment for various industries vary based on the specific requirements of every industry, which includes the size and shape of the product, as well as the type of packaging material used, as well as the intended output.Industrial packaging machines These machines are made to manage a range of products, from large and heavy objects to smaller and delicate components. They are built using sturdy construction and modern technology to create precise and efficient packaging.

Food packaging equipment Food packaging machinery made to meet the strictest hygiene and safety requirements. Many machines feature features such as easily-clean surfaces, modern sanitation systems, as well as temperature control capabilities to ensure that the food that is packaged is safe and healthy.

Cosmetics packaging machines Packaging machines for cosmetics are specifically designed to handle delicate and fragile containers such as small tubes, vials and bottles. They are fitted with delicate handling systems that make sure that the items are packaged with care.

Pharmaceutical packaging machines Pharmaceutical packaging machines meet all the requirements of safety and regulatory regulations. Many of them have advanced capabilities for labeling as well as dosing systems that's precise and tamper evident and also sophisticated labels that ensure safety and quality of the pharmaceutical products that are packaged.

Household products packaging machine Packaging machinery for household products is designed to handle a wide array of household items, including detergents, cleaning supplies , and personal cleaning products. They can be equipped with various packaging configurations with multi-head filling, as well as easy to operate controls that ensure the most efficient packaging.

Packaging machines for different industries are designed to meet the requirements of each sector. Follow the recommended [url=https://miela.fr/project/chambre-scandi-boheme/ for site info.

What Are Some Fast And Efficient Packaging Solutions For Industrial Firms?

Small Packaging in Industry Sector Automated packaging lines to handle small packaging items in the industrial sector. Multi-head weighers, small-format packaging machines , and vertical form seal sealing machines can improve the effectiveness and accuracy of the process of packaging. Automated storage management systems can also be used to optimize the storage and retrieval of small packaging.Palletizing for Long Periods- Robotic palletizing systems can be used to improve the efficiency of the palletizing process, while also reducing the risk of injury to operators. They're capable of handling various of packaging, and they can be programmed in order to be able to palletize at high speed.

Treatment of tiny vials and fragile bottles Packaging equipment that is specially designed, like blister packaging machines, are used in the beauty and cosmetics industries to handle tiny vials as well as fragile bottles. These machines ensure that vials and containers can be safely packed with minimum handling, thereby reducing the chance of being damaged.

Manufacturing equipment and packaging equipment should be selected based on the specifications of the product. It is crucial to have plans for preventative maintenance to ensure that equipment functions efficiently and smoothly. View the best conseils décoration for site advice.

Refer To A List Of The Machines And Systems Used In The Food Industry.

Blast Chillers- Blast chillers are specialized refrigeration units that rapidly reduce the temperature of hot food items to stop the development of harmful bacteria. These machines are commonly employed in the food and beverage industry to guarantee food safety and prolong the shelf life of perishable products.Rapid Cooling Solutions- Rapid cooling options such as tunnel freezers or spiral freezers are able to quickly freeze food products and cut down on the time needed to cool them down to an appropriate temperature. These solutions allow for increased efficiency, while preserving the high-quality food products.

Packaging of Trays or Cardboard Boxes. Packaging equipment like tray makers and case erectors can be used to pack food in cardboard containers or trays. They create the tray, container, and package with product in a easy, automated process.

Shrink Sleeves- Shrink sleeves can easily be applied to food or beverage containers by using shrink sleeves machines. The shrink sleeve is placed over the container and then subjected to heat, which causes it to shrink and conform to the shape of the container. This provides attractive packaging that is safe from tampering and tamper-proof. It is also food-safe.

In all cases, it is important to take into consideration the particular needs of the food and beverage product, such as size, shape, and fragility when choosing the proper packaging equipment. Additionally, the packaging equipment must be in compliance with food safety standards (such as those set out by FDA or USDA) to ensure that the products are safe for consume. View the recommended Miroir soleil en rotin for site advice.

Wraparound Case Packer With Automatic Feeds, Including Flatbed Magazines

A Wraparound Case Packer is a kind and type of packaging machine is designed to wrap the boxes in a wraparound manner. The majority of them are automated feeds that are able to adjust to fit different boxes. The machine's automatic feed system is designed for continuous feeds to boxes. It can also be adjusted to fit different sizes and shapes of boxes. Its versatility makes it an ideal option for all industries.

The wrap-around casepacker has an adjustable flatbed magazine. This magazine is adjusted to suit different sizes and shapes of boxes. This makes it possible for the machine to be used for a broad array of packaging requirements, without the need for extensive modifications or tooling changes.

In addition to its flexibility and ease of use, wrap-around case packers are specifically designed to be efficient and are usually equipped with sophisticated features such as robots that can be programmed to operate logic controllers as well as programmable logic. These features make sure that the machine functions smoothly and accurately in high production environments.

Wrap-around packagers with automatic feeds, adjustable flatbed media magazine, and the ability to adapt to different formats is an efficient and economical solution to various packaging requirements. See the top rated références des cadeaux déco pour une personne calme. for website advice.

For Industrial, Food, Household, And Pharmaceutical Items, We Can Design Automatic Packaging Systems

Tailor-made automated packaging systems are custom packaging solutions that can be customized to specific industries, including cosmetics, food, and pharmaceutical. These systems are optimized to maximize the packaging process to improve efficiency of production and fulfill the unique requirements of every industry.

Packaging configurations that are modified- These systems can be configured to meet specific industry needs. This is the case for the dimensions and shapes of the product, as well as the type and output of the packaging material.

Effective production processes- Custom-made automatic packaging systems are designed to maximize production efficiency and minimize downtime, making them perfect for production in high-volume environments.

Advanced technology. These systems are equipped with the most advanced technology. They feature robotics, controllers that are programmable, and advanced sensor technology to ensure accurate and consistent operation.

Quality control- Custom-made automated packaging systems are developed to ensure that every product is packed to the highest quality standards which helps reduce waste and improve customer satisfaction.

Cost-effectiveness- These methods can be used to lower cost of packaging while still providing excellent results.

These systems can be adapted to meet the demands of particular industries. They optimize the packaging process , and boost the effectiveness of production. Follow the best astuces décoration for more examples.

|

|

| Návrat nahoru |

|

|

|

|

Nemůžete odesílat nové téma do tohoto fóra.

Nemůžete odpovídat na témata v tomto fóru.

Nemůžete upravovat své příspěvky v tomto fóru.

Nemůžete mazat své příspěvky v tomto fóru.

Nemůžete hlasovat v tomto fóru.

|

|